Humidos

Air humidification is one of the basic types of air treatment. There are various procedures to do this. Humidification using a contact humidification process is traditional and no longer contemporary. Humidifying the air (supply air flow) using honeycomb humidification units no longer meets today’s hygiene standards. Honeycomb humidification units are still being considered for adiabatic exhaust air humidification. However, the maintenance of these systems is relatively high and people are increasingly moving away from this type of humidifier.

A second method is air humidification with steam. Hygienically favourable and without temperature losses. During humidification, this process is again very energy-intensive. Steam must be produced (> 100 °C) and this requires a large amount of electrical energy. If steam is already present in a process chain, this method is very suitable and can be easily implemented.

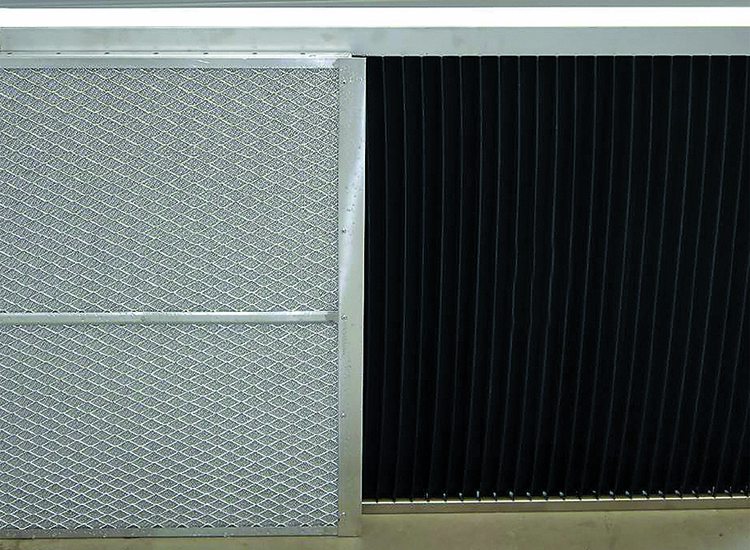

The third method is air humidification using atomising humidifiers. This procedure is very contemporary and is often used. Standards have developed enormously and durability has improved significantly. Many older models were replaced due to their lack of functional reliability. Osmosis water is required for this type of humidifier. A booster pump (osmosis system) conveys the treated water to a higher level, where it is transferred into the air flow through atomiser nozzles. A water mist is created, which humidifies the dry air to the desired saturation level. The higher the saturation limit, the longer the required humidifier length.

Mountair Humidos low-pressure atomising humidifier without internal booster pump

The low-pressure atomiser is built as a stand-alone system without its own booster pump. The humidifier is fed from a water treatment/osmosis system with an integrated booster pump. Exactly 4–5 bar flow pressure is required at the humidifier inlet (supply). The supply is connected to the valve block with the zone and drain valves on the outside of the Monobloc. The zone-dependent water distribution system is installed from the valve block to the humidifier based on the project-specific design. The chrome steel nozzle rack with the low-pressure atomiser nozzles is installed in the humidifier interior.

The Humidos low-pressure humidifiers can be designed as 3-7-15 or 31-stage humidifiers. The zone valves are defined depending on the air volume flow, humidification level and system cross-section. For example, 4 zone valves (A/B/C/D) = 15 stages.

If the humidifier is switched off, the external drain valve is activated and the nozzle rack installed in the air flow can empty (hygiene regulation). Each Humidos low-pressure humidifier has its own control unit (control cabinet, mounted on the outside of the Monobloc and wired internally with zone and drain valves). The humidos control is controlled from the higher-level Monobloc controller with a Release and 0–10 V signal (control system/building automation ). Internal power regulation is not carried out, the humidifier follows the signal given externally (8V = 80% humidifier output based on the maximum dimensions).